Abstract

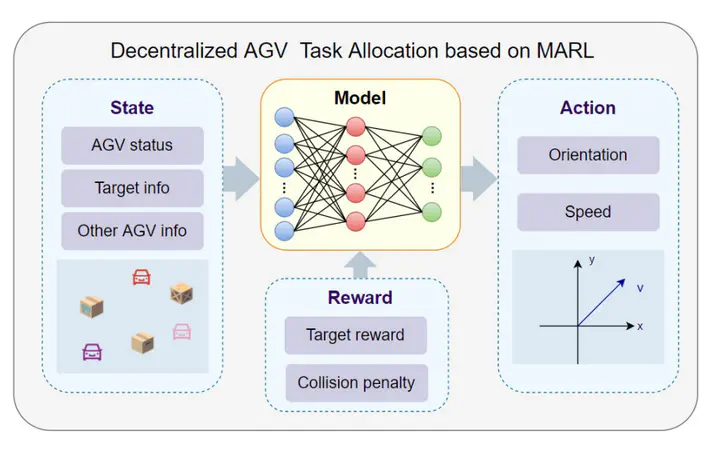

Automated Guided Vehicles (AGVs) have been widely used for material handling in flexible shop floors. Each product requires various raw materials to complete the assembly in production process. AGVs are used to realize the automatic handling of raw materials in different locations. Efficient AGVs task allocation strategy can reduce transportation costs and improve distribution efficiency. However, the traditional centralized approaches make high demands on the control center’s computing power and real-time capability. In this paper, we present decentralized solutions to achieve flexible and self-organized AGVs task allocation. In particular, we propose two improved multi-agent reinforcement learning algorithms, MAD-DPG-IPF (Information Potential Field) and BiCNet-IPF, to realize the coordination among AGVs adapting to different scenarios. To address the reward-sparsity issue, we propose a reward shaping strategy based on information potential field, which provides stepwise rewards and implicitly guides the AGVs to different material targets. We conduct experiments under different settings (3 AGVs and 6 AGVs), and the experiment results indicate that, compared with baseline methods, our work obtains up to 47% task response improvement and 22% training iterations reduction.